Thermal Evaporation and Its Impact on Deposition Processes

Article written by The Digital Terror

Thermal evaporation utilizes high temperatures to create thin films.

When it comes to understanding a thermal evaporation system, one can compare it to a pan of boiling water on a stove. Drops of water begin to form on the ceiling of the kitchen. After, the boiling water is then transferred to a bowl, then quickly placed into a freezer. What happens? A layer of ice will form above the bowl. This is thermal evaporation in a nutshell. With a high enough temperature, the same evaporation cycle and condensation can be used to create thin films of materials that remain stable within a vapor state. When this technique is used to apply thin films in high vacuum environment, it’s known as thermal evaporation.

Breaking Down Thermal Evaporation

The heat provided is through either Joule heating through a refractory metal element – resistive evaporation, or through a beam of high energy electrons like electron beam evaporation. Other sputter deposition techniques like laser ablation or cathodic arc deposition essentially use the same technique in the form of a high power laser or an electric arc – but this is rarely referred to as thermal evaporation.

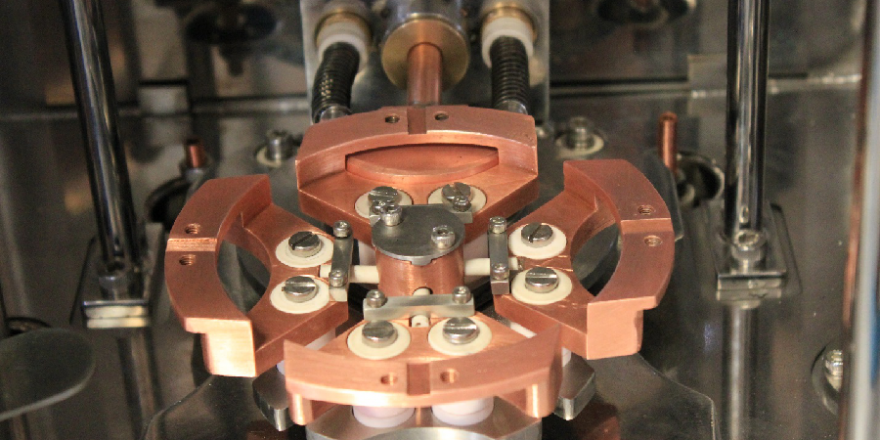

Another approach to thermal evaporation is the process of electron beam evaporation which uses a beam of high energy electrons to create a thin film layer on a substrate. The evaporant will sit on a water-cooled copper hearth and a beam of electrons are emitted from a filament to strike and begin the melting process. The benefit of this is that even the highest temperature materials, like refractory metals, can be melted.

Denton Vacuum, LLC manufactures quality sputtering systems that are durable, advanced, and cost-friendly.